ippd Fundamentals Explained

In either case, pre-prototype typically encompasses Phase 1( Concept Generation) through Phase 3 (Principle Development & Screening), and it might continue through Stage 6 (Item Advancement) when a business has typically fully devoted to a concept and the design is "frozen." Specified by Peter A. Koen as "frequently disorderly, unforeseeable and unstructured", this preliminary period may take up to 50% of the overall item development time and includes 5 front-end elements.

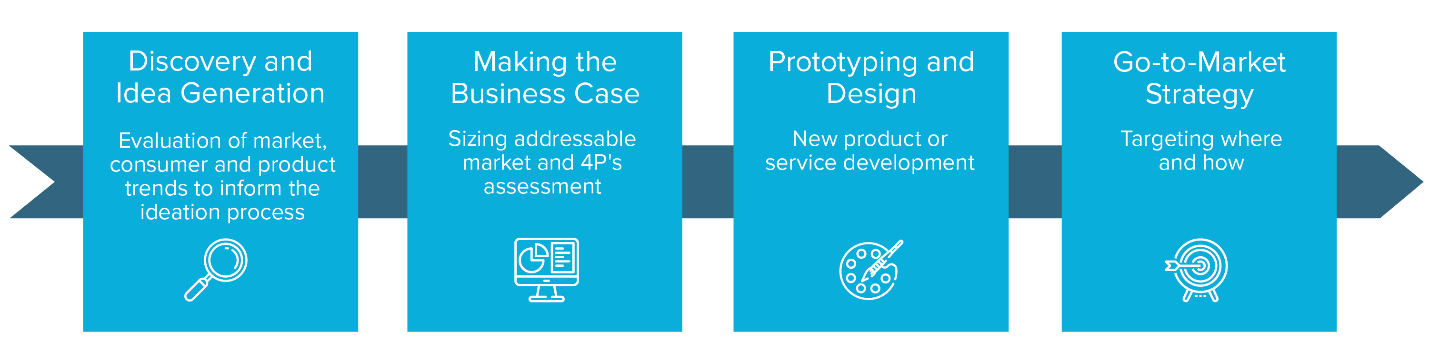

The Pre-Prototype Phases of the NPD Process A service or technical requirement that the company or individual realizes by design or default that they might wish to pursue to catch competitive advantage, react to a danger, or fix a problem The majority of embryonic kind of a brand-new product, service or envisioned service Has a defined form (i.

Pre-Prototype meanings Why is Pre-prototype Important? The power of pre-prototype owes to the fact that at the start of the NPD procedure, the degree of flexibility in design and influence on product results are high, whereas the costs for modifications are low. This front-end advantage is limited by the truth that the amount and certainty of details is low compared to later phases at the same time.

The Ultimate Guide To New Product Development: 3 weeks to prototype success

Impact, cost of changes, and info throughout the innovation process Regrettably, lots of business have inadequate ways to formally track or manage these early phases of the NPD process, and the biggest chance to save time and money is gone prior to the clock even starts. It is during this vital in advance time period that a collective relationship with a contract maker, a totally capable outsourcing partner, can provide the most value to a business.

References Dr. Scott Edgett and Dr. Robert Cooper Biographies. (1996-2005). Item Development Institute Inc. Retrieved from Koen, P.A. (May 25, 2004). Undertstanding https://lanpdt.com/ : A Common Language and Structured Photo. Stevens Institute of Technology. Obtained from http://www. slideshare.net/Brand, Genetics/koen-fei Related Articles Following these techniques will change how your company deals with its contracting out partners.

Bi-Link is an international ISO-13485 accredited making business providing a full-range of capabilities consisting of open innovation, prototyping, injection molding, metal stamping, and assembly services to the Automotive, Wireless, Medical and Customer markets. A dual-degreed engineer, Marion began her career with Ford Motor Business as a Design Release Engineer, and she spent the next 20+ years in the Automotive industry holding gradually crucial positions in Item Engineering, Operations, and Marketing.

<